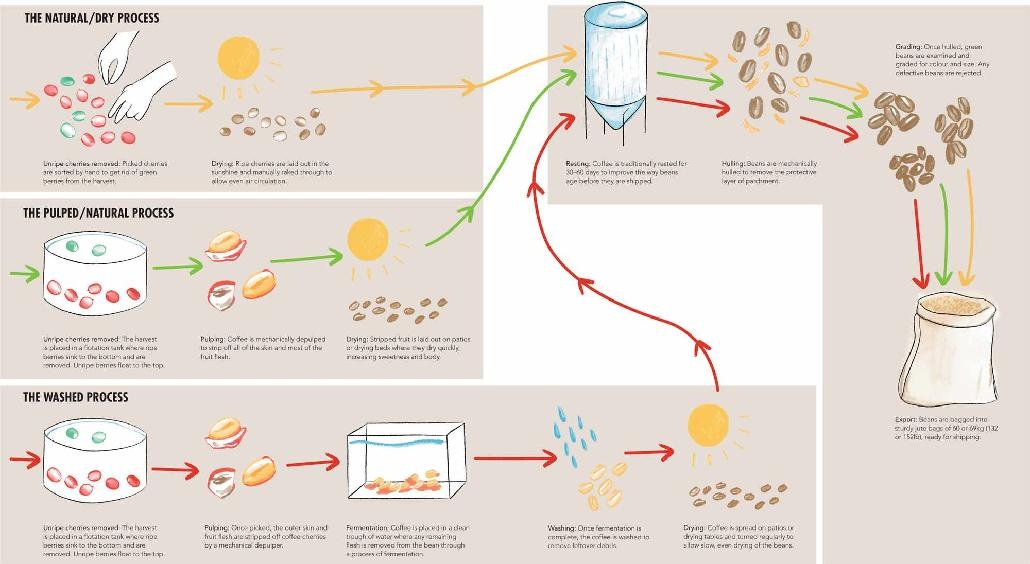

How a coffee is processed after harvest can have a dramatic effect on the resulting cup, so it has become an increasingly important part of how it is described and sold. It would be a mistake to believe that coffee producers have flavour in mind when they choose their processing methods. A very small percentage do, but for most producers the goal is to ensure the processing causes the least possible incidence of ‘defect’ and causes no drop in the quality, and thus the monetary value, of the coffee.

A fter harvest, the coffee cherries are taken to a wet mill to separate the beans from the flesh and dry the beans so they are safe for storage. Coffee beans start with a moisture content of around 60 per cent, and should be dried to around 11–12 per cent to ensure they do not rot while waiting to be sold and shipped. A wet mill can be anything from a small collection of equipment on an individual farm, to a very large industrialized facility for processing enormous amounts of coffee.

The wet mill processes coffee from the cherry stage to the parchment stage, when the bean is dry but still covered with its layer of parchment or pergamino. Most believe that the coffee is pretty well protected by this outer layer, and that it does not really begin to degrade until the coffee is hulled to remove the parchment at the last possible moment before the coffee ships.

The term ‘wet milling’ is slightly misleading as some producers use very little, if any, water in the processing methods they use. It does, however, make the distinction between this initial processing and the later stage when the hulling and grading takes place, known as ‘dry milling’.

There is no doubt that processing can have a massive impact on the cup quality of the coffee, and there is a growing trend for skilled producers to manipulate the process in order to yield specific qualities in the cup. However, these producers are very rare on the global production scale.

The goal of processing for most is to make the coffee as profitable as possible and this is taken into account when a producer chooses which processing method to use. Some processes require more time, investment or natural resources than others, and so it is an important decision for any coffee producer.

DEFINING ‘DEFECT’

The term ‘defect’ is used quite specifically in coffee. It is used to describe individual beans that have developed problems that result in bad flavours. Some defects can be spotted by taking a look at the raw coffee, while others only come to light when the coffee is tasted.

A mild defect might be a bean that has been damaged by insects, and this is easy to spot. A more serious problem is a phenolic coffee, where the coffee has a very harsh, metallic, paint-stripper flavour, mixed with notes of sulphur (it is as bad as it sounds). The cause of this defect isn’t well understood yet. Bad processing can also cause defects, including giving the coffee a fermented flavour and an unpleasantly dirty, almost boozy quality. It can also add a taste reminiscent of barnyards and rotten fruit.

THE NATURAL PROCESS

Also known as the dry process, this is the oldest method of processing coffee. After harvest, the coffee cherries are spread out in a thin layer to dry in the sun. Some producers spread them out on brick patios, others use special raised drying tables, which allow a better airflow around the cherry, resulting in more even drying. The cherries must be turned regularly to avoid mould, fermentation or rotting taking place. Once the coffee is properly dry, the outer husk of skin and dried fruit are removed mechanically, and the raw coffee is then stored before export.

The natural process itself adds certain flavours to the coffee, sometimes positive but often quite unpleasant. However, if there is no access to water this may be the only process open to the producer and is therefore common in places like Ethiopia, and also parts of Brazil. Worldwide, the dry method is generally deemed only suitable for very low-quality or unripe coffee, and the bulk of coffee produced this way is processed as cheaply as possible as it usually ends up in the domestic market and has very little value. It seems counterintuitive that a producer would invest in the drying tables necessary for the little return on offer. However, there are those who choose this method to process high-quality coffee, and they often find the process to be more expensive due to the additional labour involved in the attentive, careful drying of the cherries.

This process remains quite traditional in places, and there is certainly demand for the cup qualities that a carefully processed lot can have. The process will often add fruit flavours to the coffee, regardless of variety and terroir. These are usually described as hints of blueberry, strawberry or tropical fruit, but sometimes with negative terms like barnyard, wild, ferment and manure.

High-quality naturals polarize those who work in coffee. Many see value in coffees that taste spectacularly fruity, and believe they are extremely useful for showcasing the possibilities of flavour that coffee has to offer. Others find the wild flavours unpleasant, or have concerns about buyers encouraging producers to process more of their coffee through the natural process. With such an unpredictable process, a high-quality lot could be damaged irreparably and significantly reduce the producer’s income.

Dry processing is the oldest method with which to treat picked cherries. They are dried in the sun and turned regularly to prevent fermentation, mould and rot.

Dry processing is the oldest method with which to treat picked cherries. They are dried in the sun and turned regularly to prevent fermentation, mould and rot.

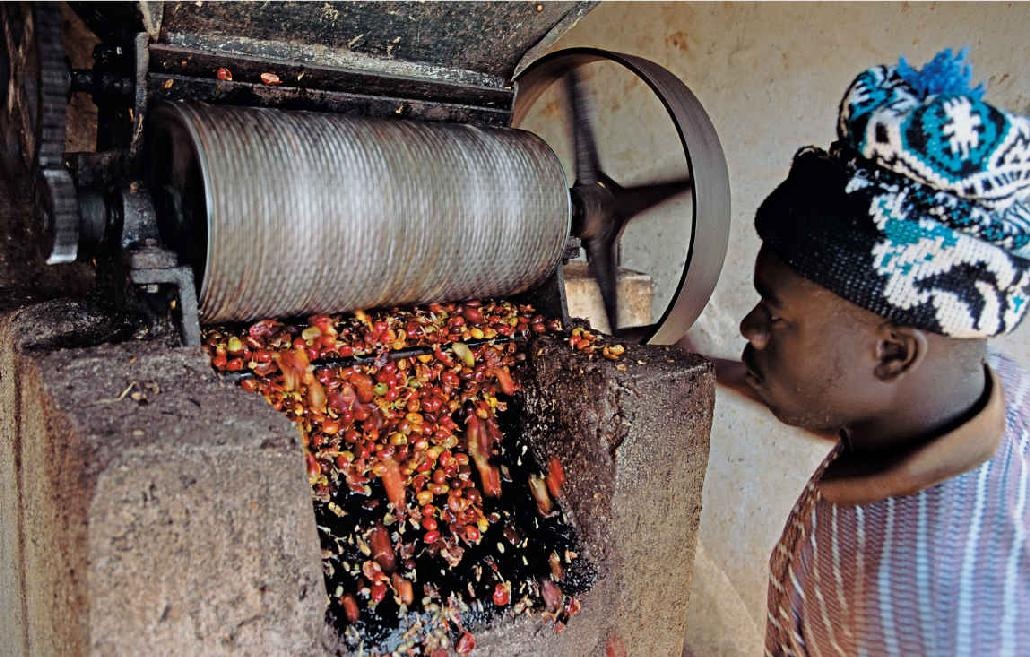

A depulper machine is used to strip flesh off coffee cherries. They are then moved to a clean tank where the remaining flesh is removed through fermentation.

A depulper machine is used to strip flesh off coffee cherries. They are then moved to a clean tank where the remaining flesh is removed through fermentation.

DRYING SPEED AND STORAGE POTENTIAL

While still at an early stage, research seems to suggest that drying coffee very slowly and very evenly can have benefits not only to quality in the short term, but also to how long a coffee will retain its good flavour when stored in its raw state. Coffees dried too quickly can lose their attractive qualities shortly after being delivered to the roaster, in some cases within a few months or even weeks, which is bad news for both the roaster and the end consumer.

THE WASHED PROCESS

The goal of the washed process is to remove all of the sticky flesh from the coffee seed before it is dried. This greatly reduces the chance of something going wrong during drying, so the coffee is likely to be worth more. However, this particular process is much more expensive than the others.

After picking, the coffee cherry has its outer skin and most of the fruit flesh stripped off using a machine called a depulper. The coffee is then moved to a clean tank or trough of water where the remainder of the flesh is removed by fermentation.

The fruit flesh contains a lot of pectin and it is firmly attached to the seed but the fermentation breaks down the remaining flesh enough for it to be washed away. Different producers use different amounts of water during the fermentation stage, and there are some environmental concerns about this method, partly due to the eventual fate of the waste water, which can be toxic.

The amount of time that fermentation takes depends on several factors including the altitude and ambient temperature. The hotter it is, the faster this process will occur. If the coffee is left too long to ferment then negative flavours can creep in. There are many different methods for checking whether the process is finished. Some producers rub the coffee as it will squeak if the fruit flesh has broken down, leaving the seed completely smooth. Others put a stick into the tank and if it stands up, supported by the slightly gelatinous water full of pectin, then the process is done.

After fermentation, the coffee is washed to remove the leftover debris, then it is ready to be dried. This is usually done in the sun by spreading out the coffee on brick patios or raised drying tables. In the same way as the natural method described above, the coffee must be turned regularly with large rakes to ensure slow and even drying.

Where there is a lack of sunshine or excess humidity, some producers use mechanical dryers to dry the beans down to a moisture content of around 11–12 per cent. In terms of cup quality, mechanical drying is often considered inferior to sun drying, and it seems that even drying in the sun on a patio may be too fast to achieve the best possible quality (see Drying Speed and Storage Potential). While many producers of high-quality coffee choose the wet process in an effort to reduce defect, it can also have an impact on the cup quality. Compared to other processes, wet-processed coffees tend to present a higher level of acidity, increased complexity and what is described as a cleaner cup. ‘Cleanliness’ is an important term used in coffee to indicate the absence of any negative flavours, such as off tastes or unusual harshness and astringency.

HYBRID PROCESSES

THE PULPED NATURAL PROCESS

Mainly used in Brazil, this process is the result of experiments run by a coffee-processing equipment manufacturer called Pinhalense. The idea was to produce coffees with high cup quality using less water than that used in the washed process.

After picking, the coffee is mechanically depulped, stripping all of the skin and much of the fruit flesh from the beans. From here it goes straight out to dry on patios or drying beds. With less flesh surrounding the beans there is a decreased risk of defect, yet there is still enough sugar in the surrounding fruit to see a noticeable increase in sweetness and body in the coffee. This process still requires careful drying after depulping.

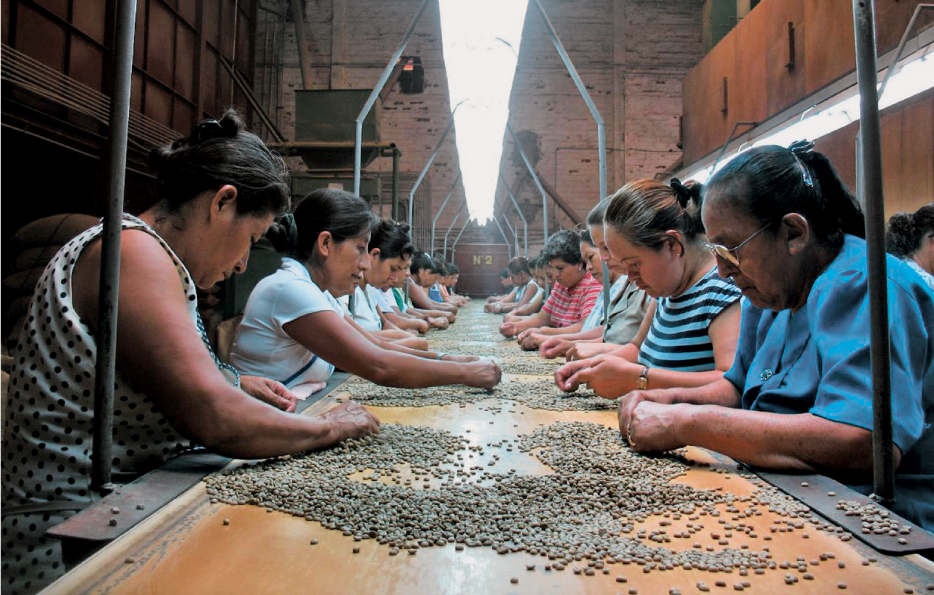

Hulled coffee is sorted by hand to grade bean size and colour, and remove any defects. This process is time-consuming but creates coffee of a much higher quality.

Hulled coffee is sorted by hand to grade bean size and colour, and remove any defects. This process is time-consuming but creates coffee of a much higher quality.

THE HONEY (MIEL) PROCESS

This process is very similar to the pulped natural process but used in a number of Central American countries, including Costa Rica and El Salvador. The coffee is mechanically depulped, but the method uses even less water than the pulped natural process. The depulping machines can usually be controlled to leave a specific percentage of the flesh on the beans. The resulting coffee is then referred to as one hundred per cent honey or twenty per cent honey, for example. The name miel is the Spanish term for the fruit mucilage, meaning ‘honey’.

With larger quantities of flesh being left on the beans, there is a higher risk of fermentation and defect when the coffee is dried.

THE SEMI-WASHED/WET-HULLED PROCESS

This process is common in Indonesia, where it is known as giling basah. After picking, the coffee is depulped and then briefly dried. Instead of drying the coffee to a moisture content of 11–12 per cent as the other processes do, in the semi-washed process the coffee is only dried to 30–35 per cent. It is then hulled, stripping off the parchment and exposing the green coffee beans beneath. The naked beans are then dried again until they are dry enough to be stored without the risk of rotting. This second drying gives the beans a distinctive deep swamp-green colour.

The semi-washed process is the one exception to the practice of keeping the parchment on the beans until just before shipping. It is considered by many to result in a form of defect, but the market has come to associate the flavours with coffees from Indonesia and therefore does not demand an end to the practice. Semi-washed coffees have lower acidity and more body than other coffees, and the process also creates a number of different flavours such as wood, earthy, mustiness, spice, tobacco and leather. There is strong disagreement within the industry over whether or not this is desirable. Many feel that these flavours dominate the flavour of the coffee (in the same way the natural process does), and we rarely get to find out how coffees from Indonesia really taste. However, there are some Indonesian coffees that are processed by the wet method, and they are worth looking out for. It should be clear on the packaging as they should be described as ‘washed’ or ‘fully washed’.

HULLING AND SHIPPING

When they leave the wet mill, the beans are still enclosed in their layer of parchment (unless they have been processed by the semi-washed method). Now the moisture content is low enough for the coffee to be stored without risk of rotting. Traditionally, coffee is intentionally stored at this stage in reposo (at rest) for thirty to sixty days.

The traditional practice of holding the coffee in reposo has not been fully researched, although anecdotal evidence suggests that if this step is missed then the coffee can taste green and unpleasant until it has aged further. There is also evidence that this stage influences how well the coffee will age once shipped, probably linked to the moisture content within the coffee.

At the end of this period the coffee is sold and then hulled to remove the parchment. Up until this point the parchment has provided a protective layer, but it also adds weight and bulk to the coffee so it is removed to make shipping less expensive.

The hulling is done mechanically in a dry mill (as opposed to a wet mill where the coffee was processed to remove the flesh and dry the beans). Dry mills also usually have equipment to grade and sort the coffee. Once hulled, the green coffee beans can be passed through a machine that examines the colour and rejects any coffee with obvious defects. The coffee can be sorted by bean size using large shaking sieves with varying hole sizes, and finally it is graded by hand.

This time-consuming process is performed at a large table with a central conveyor, or sometimes on large patios, usually by women rather than men. They pick through their allocation of coffee and remove all the defects they can, sometimes within a given time frame controlled by an automated conveyor. This is a slow process, adding significant cost to the coffee, but also massively increasing its quality. It is undeniably a difficult, monotonous job and it is right that high-quality coffees cost more, so that the people who do this difficult work can be better paid.

Workers sew up 60-kg (132-lb) jute bags near Yirgacheffe, a coffee-growing community in south-central Ethiopia. Their popular product is exported around the world.

Workers sew up 60-kg (132-lb) jute bags near Yirgacheffe, a coffee-growing community in south-central Ethiopia. Their popular product is exported around the world.

BAGGING

The coffee is now ready for bagging, either into 60kg (132lb) or 69kg (152lb) jute bags, depending on the country of origin. In some cases the bags are lined with a protective material, such as a multilayer polyethylene, to make them resistant to moisture, or the coffee can be vacuum-packed and shipped in cardboard boxes.

Jute has long remained the material of choice because it is cheap, accessible and has little environmental impact. However, as the speciality coffee industry is increasingly concerned with the condition of coffee during shipping and in ongoing storage, new materials are being explored.

SHIPPING

Coffee is generally transported from its country of origin in shipping containers. These hold up to three hundred bags of coffee, although low-quality coffees are sometimes just tipped into a giant lining covering the walls of the container, as the waiting roaster will process the entire container on the day it arrives. The containers are emptied out like dump trucks into a receiving station at the roasting facility.

Transporting coffee in container ships has a relatively low impact on the environment (certainly compared to other aspects of the coffee industry), and it is also relatively cheap. The downside is that the coffee can be exposed to both heat and moisture that may damage its quality. Shipping is also a complicated process, with bureaucracy in many countries causing roasters huge amounts of stress as containers of coffee sit for weeks or even months in hot, humid ports waiting for their paperwork. As air freight remains both an environmentally unfriendly and financially unsustainable alternative, many in the speciality coffee industry remain frustrated by this aspect of the business.

SIZING AND GRADING

Coffee has, in many countries, been graded by size longer than it has been graded by quality. In fact the two things are still considered related, although technically they are not. Different countries will use different terminology around their grading (see Common Size Grades).

Grading is generally done with sieves, numbered to indicate the size of the perforations. Traditionally the even numbers (such as 14, 16 and 18) were used for Arabica, while odd numbers were used for Robusta. Once the coffee is hulled it is mechanically shaken through layers of sieves to separate out the different grades.

Peaberry (PB) is a grade based on the smallest whole beans (not the broken pieces though). Peaberries occur when a coffee berry has just one seed inside rather than two. They are considered to have a greater intensity of flavour, although this may not be universally true. It is always an interesting experience to compare the flavour of the the peaberry selection of a coffee against that of the larger beans.

While larger beans aren’t necessarily better, the advantage of having a relatively small size range is that roasting the coffee is easier, and the resultant roast is likely to be more uniform. This is because coffee beans of different sizes also have different densities. During roasting, the smaller coffee beans, or the less dense ones, will roast much faster than the larger, or denser beans. This will mean that at least a portion of the coffee in a mixed batch will not have reached the ideal roast level.

COMMON SIZE GRADES These are the most common sizing grades used in the following coffee-producing areas.

COLOMBIA Supremo and Excelso are very common grades. Excelso is screen sizes 14–16, and is smaller than Supremo which is sizes 16–18 (or above). Colombia pioneered how it sold its coffee, and uses grades like this to emphasize its quality.

CENTRAL AMERICA Here the larger sizes are traditionally referred to as Superior (again, emphasizing quality through size). Peaberries are known as caracol.

AFRICA The largest screen size is generally considered AA, then AB and then A. Coffee-producing countries such as Kenya have a strong focus on quality relating to size grading and AA lots tend to sell for higher prices in their internal auction system.